reclaimed tube films

Environmentally friendly polyethylene tube films made from reclaimed materials

“Normal” polyethylene is a by-product of the oil extraction process. The basis of this material is a gas called ethylene. Unfortunately, many people use products made from polyethylene once – but then what…?

That’s right: recycle them! Polyethylene is particularly easy to recycle. No matter how thick, homogeneous PE can pass through almost unlimited cycles of being melted down and turned into new products.

Recycled polyethylene, also referred to as reclaimed polyethylene, can either be mixed into conventional production processes or replace raw materials entirely. The recycling process preserves the original properties and characteristics of polyethylene.

Different qualities of reclaimed material

There are also differences in the production of reclaimed polyethylene – differences that can be traced back to the origins of the source material. For example, reclaimed material derived from domestic recycling might well tickle a sensitive nose or two. Plus, producing polyethylene from materials reclaimed through domestic recycling is often more expensive and consumes key resources. In addition, domestically recycled materials tend to produce films with a slightly yellow-brown-grey tinge.

However, if reclaimed polyethylene is produced using materials recycled from industrial sources, it is almost impossible to tell the difference between reclaimed and original polyethylene – and such material can be used to create translucent PE films.

In order to uphold the quality of our products, we exclusively offer PE films containing material reclaimed from industrial sources.

LDPE and HDPE: One reclaimed material – two films

When treating and processing reclaimed material, monomers form long chains of molecules called polymers. These polymers can in turn be used to produce films in two different qualities: HDPE and LDPE.

Each of these polyethylene (PE) films offers specific advantages. In the following, however, we will direct our focus solely to translucent LDPE film, which we offer in rolls of tube film in various thicknesses and widths.

LDPE film offers impressive translucency, allowing you to see exactly what you have packed and how much of it – and enabling your customers to see the contents straight away without having to open the packaging.

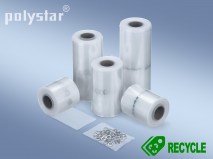

A selection of PE tube film made from 100% reclaimed materials

There is a range of materials on the market, from PE films made from varying percentages of reclaimed material to “pure” PE films. In a bid to remove the complexity, the recycled LDPE films we offer are always made from 100% reclaimed materials.

Our translucent LDPE tube films come in widths of 100 mm to 500 mm and are 0.10 mm (100 µm) thick.

Depending on the width, rolls of translucent tube film can be ordered in two lengths: a short 25 m roll and a long 250 m roll. Small rolls of 25 m of film have a manageable diameter of approx. 7–13 cm. Longer rolls of PE tube film also have a larger diameter, generally around 25–38 cm. We offer reclaimed polyethylene tube films in a wide range of different sizes!

LDPE tube film or ready-made LDPE bags – which is right for me?

Both options have very specific advantages. Although a roll of PE tube film allows you to create individual PE bags with different lengths for different contents, the dimensions of ready-made polyethylene flat bags are pre-determined. In some cases, specific storage arrangements may need to be made to store bags of different dimensions; on the other hand, having a stock of ready-made bags saves the time required to produce them. Opting for rolls of LDPE tube film eliminates the need for such storage arrangements – provided that you only require one width of PE flat bags.

Ultimately, there are two factors to consider when deciding between translucent tube film and ready-made polyethylene bags:

- Procurement price – in this regard, PE tube film offers significant advantages, though the time required to individually produce bags must be included in cost calculations.

- Operational work processes

I see your reclaimed LDPE tube films in stock – do you offer anything else?

The answer here is an emphatic YES! Whether translucent LDPE centre-folded film, coloured anti-static flat bags or tube films with translucent antistatic additives, LDPE bags with and without side pleats, coloured or printed LDPE tube films, UV-resistant PE tube films in different thicknesses, or… just about anything else – when it comes to reclaimed polyethylene in different proportions, the possibilities are limitless.

Don’t hesitate to ask! We would be happy to put a proposal together for you.

By the way…

… whether you need to process PE tube films, PE centre-folded films or PE flat bags, and whether or not your films contain reclaimed materials, we also have polystar® film sealers to help you do just that. Check out the “Industrial packaging” and “Film sealing devices for industrial use” sections of our website for more details.