Sterilization packaging material

Heat-sealable sterilisation films – for more safety

How can sterile films provide more safety? Simple: if used correctly, these sterile barrier systems prevent micro-organisms from entering the sterile packaging. And what exactly does that mean? The items to be sterilised, e.g. instruments that can be used several times, are packaged in sterile films, sealed and then sterilised. The sterilisation process takes place, for example, in an autoclave. Afterwards, the instruments or other objects can then be safely stored and transported in the packaging until they need to be used again.

Heat-sealable sterilisation films have two different sides

The first side of the sterile barrier system is made of medical paper and the other side is manufactured from a transparent – and impermeable – film. Of course, the two sides have different functions:

- The side made from medical paper plays an important role in steam sterilisation. The steam can enter through the pores in the paper and thus sterilise the contents of the packaging. After sterilisation, the medical paper no longer lets anything through – germs and viruses, etc., cannot penetrate the packaging.

- The transparent side of the sterile barrier system allows the contents to be seen at any time.

- Clear markings on the edge of the packaging indicate whether or not the contents are sterile.

A plethora of regulations...

...guarantee a level of safety that extends to the patient and medical staff. It goes without saying that the cleanliness and sterility of all instruments or items used on or in the patient is an absolute must. In order to ensure that this level of safety is actually maintained, there are a plethora of regulations that govern the sterile packaging process and the subsequent storage and transportation processes. The most important ones are the standards DIN EN ISO 11607, EN 868-5 and DIN 58953-7 as well as the recommendations of KRINKO (Hospital Hygiene and Infection Prevention Commission of the Robert Koch Institute). Upon request, we can explain the content of the above-mentioned standards and recommendations in more detail.

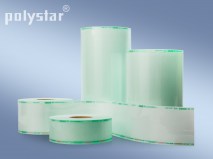

Wide range of sterilisation films

Whether you choose pre-made bags or roll products – with or without gusset – is up to you. If you always need the same packaging size, bags are the more appropriate option.

However, if you work with reusable products of different sizes, it would be better to use sterilisation rolls. This will allow you to individually set the length for your packaging.

Sealing sterilisation films in line with regulations using sealers by polystar®

Sterilisation films should be sealed using a validatable packaging process. polystar® film sealers and continuous rotary heat sealers bearing the mark “validatable” or “validatable sealing process” are suitable for this. These sealing devices have been specially designed for sealing sterilisation films in bag or roll form and they monitor and document the parameters required for the sealing process: Temperature, sealing time or throughput speed (device-dependent) and pressure. The process parameters involved in each sealing procedure can be saved on a USB stick or – depending on the model – printed on the packaging itself. We are happy to advise you on the topics of validation, calibration, seal seam strength tests and seal checks – just give us a call.

By the way...

...we also have the perfect polystar® film sealers for sterilisation films in bag or roll film with and without a gusset. Just have a browse on our homepage in the “Medical packaging” section.