Packaging films: to protect your products

Packaging films are a dime a dozen. And films – no matter what they are made of – have different functions for ensuring that your carefully made products reach your clients safely and in one piece.

Packaging films serve a direct protective function for your products during storage and transportation. Furthermore, films can also take on an advertising and informative function when designed accordingly. Films offer an additional advantage if they also have a dosing and withdrawal function.

Packaging films can do all that. There are so many different kinds: transparent or opaque, simple protection or fancy sales packaging, barrier properties or not, zip closure, aroma valve, monofilms, composite films, aluminium or paper composite... which film is best?

Well, it depends entirely on your product...

The colourful world of packaging films

The sheer quantity of different packaging films is mind-boggling and needs to be carefully and intensively sifted through in order to find what’s right for you. Admittedly, this is not one of our core competencies, but we have a large network of packaging film manufacturers to drawn on. But as soon as you have your film in your hand, we can step in with a polystar® film sealer so you can have properly packaging products.

Opting for “simple” films

More often than not, simple packaging that serves a mere protective function is sufficient – “simple” in this case does not equate to “inferior” or the like. Perhaps you are looking for a transparent polyethylene film for your industrial products so that they can be protected from contamination during storage and transportation. Or perhaps you are looking for a functional PE film bag to be used as primary packaging.

Or perhaps you need sterilisation packaging for medical applications.

Sometimes, simple is better.

Large stock of LDPE tube film, reclaimed PE tube films and sterilisation films

We can help you with our extensive and comprehensive stock. We have consciously decided to use two warehouses for industrial packaging and one for medical packaging. This is certainly more costly than storing all films in one place, but it means that the relevant films are available to you faster and in smaller quantities.

We have been supplying PE tube film since time immemorial. These films are manufactured in Germany and therefore have a low carbon footprint. We offer a wide selection of conventional LDPE tube film on rolls in different widths, film thicknesses and running lengths.

Our supply of tube film made from 100% reclaimed industrial PE from Germany is somewhat smaller, as we have only just started stocking it. This product therefore has an even smaller carbon footprint, as the original product has had new life breathed into it thanks to the recycling process.

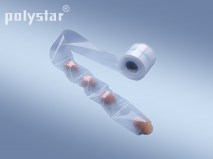

In the medical sector, we are particularly interested in sterilisation packaging. Here, too, you have various different options, for example TYVEK® films. We have gone for the “classic” variant of sterilisation film – one side paper, the other side plastic.

As a general rule, all film types mentioned above are ready to be shipped.

Tube film or pre-made bags – what should I go for?

As much as we would like to, we can’t make this decision for you. Both options have their advantages and disadvantages.

If you decide on tube film, the purchase costs are pretty low. And they are also flexible in terms of individual bag length. However, the bags must first be manufactured by you, so production costs need to be added on to the purchase price.

Vice versa, if you choose pre-made flat bags, you are saved the costs of individual bag production. But because these bags are already pre-made, the purchase price is accordingly higher than for tube film. And if you require different bag widths and lengths, the expense for storage also goes up.

Do you have anything else?

Of course! Just tell us what you need: Polyethylene centre-folded film, LDPE flat film on rolls, PE flat bags with a side or base seam, PE films with anti-static properties, smooth LDPE tube film, coloured, transparent or opaque tube films, UV-resistant films made from polyethylene, different film thicknesses or widths ... anything is possible. As a general rule, the production lines are set up for your individual requirements, so expect higher purchase quantities for special dimensions as well.

We know that there are different requirements in the field of medical packaging as well, and we would be more than happy to cater for them – just let us know!

Did you know...

...almost all commercially available thermoplastic and heat-sealable packaging films can be sealed with a polystar® film sealer? This applies not only to the industrial but also to the medical packaging sector. Just have a browse on our homepage and explore the world of plastic film packaging.