Film sealing devices for industrial use

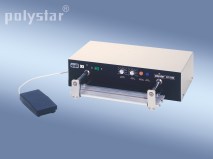

Electromagnetic table-top sealers, vertical sealing jaws, electronic regulation

polystar® 410 M series

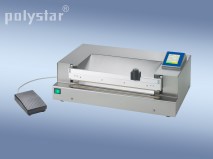

Electromagnetic table-top sealers, horizontal sealing jaws, electronic regulation

polystar® 410 HM series

Industrial impulse sealers by polystar® – they won’t let you down

Are you looking for an affordable product for reliably packaging your valuable products without having to fork out huge sums of money for a large packaging machine? Do you still need a film sealer that is robust, durable and suitable for continuous use? Is your packaging a bag or tube film or do you use both alternately? Then we have exactly the right solution for you!

The industrial impulse sealers from polystar® combine exactly the features you are looking for. The wide selection of different handling options – mobile or stationary working, hand or foot operation – make your packaging work a breeze.

Mobile sealing...

...of long rolls of film is possible thanks to the polystar® 120 GE impulse generator and the various tong sizes and types. But film bags, for example made of polyethylene, can also be quickly and durably sealed.

This film sealer can also effortlessly handle large bags and pouches and/or valve bags with an internal PE coating. The only thing to be aware of in this type of packaging is that the area of the sealing seam must be completely dust-free.

You will need your hands...

...for the polystar® lever arm thermal impulse sealers. This sealer is available in three different lengths and two different designs. In the simple variant of the film sealer, the lever arm has to be held down during the sealing process. In the variant with the holding magnet, you are spared this task. These film sealers are commonly used to individually package spare parts or other products in bags individually produced from tube film.

Fill the space you save with the compact film sealers by incorporating additional work aids so that you can process film bags and/or tube films with minimal fuss.

and with perfect footwork...

...come perfect results with the polystar® film selaers with vertical sealing barrs. Just place the film between the heating elements, start the sealing process using the foot switch and the packaging is done. With this thermal impulse sealer, you can produce individual bags from a roll of tube film or seal pre-made film bags.

The “eco” designation is given to the film sealers with the electronic control system. Not only can the temperature, sealing time and cooling time be set precisely, the intelligent control system detects the residual heat in the heating elements and then just makes up the difference to the desired temperature. This makes it “eco” in a dual sense, as it saves energy and reduces heating element wear.

Additional work aids such as a cutting device, plug-in work table, film dispenser for a single roll of tube film and a film roll magazine for several rolls of tube film are the perfect supplements to the film sealers. If you need some inspiration for the perfect work station, just get in touch and we will provide some insights.

The polystar® thermal impulse sealers with horizontal sealing bars are also foot-operated. This series of packaging machines seals pre-made bags and pouches measuring up to 1000 mm in width. For heavy film bags, the lift truck with the small roller track is the ideal work aid for the thermal impulse sealer.

Does your bag need a bit of “room for movement”? No problem, we have just the thing: The sealing bars of the film sealer are mounted in a U-profile so that you can vary the overhang of the film bag almost limitlessly.

The film sealers with horizontal sealing bars are available in four different working widths and – as with the vertical sealing bars – there is the tried-and-tested potentiometer variant and the eco variant with an electronic control system.

If validation is a concern and you need your sealing processes monitored and process parameters recorded...

...the polystar® 430 M film sealers are the right choice for you. Furthermore, these packaging machines can handle most film materials – whether they are simple monofilms in bag or tube film form or more challenging films, such as TYVEK®. The sealing parameters required in each case are input via a touch screen display and can even be permanently stored in a programme memory. Then, just operate the foot switch and your bag is sealed.

Supplement your film sealer with a cutting device, plug-in work table, film dispenser for a single roll of tube film or a film roll magazine for several rolls of tube film and you will have a complete work station for perfectly packaged products.

By the way...

...our film sealers use different film-sealing techniques. As the name suggests, the thermal impulse sealers use a thermal impulse that triggers the actual sealing process.

However, the continuous rotary heat sealers use a different film-sealing technique and are operated in an entirely different manner. These devices and machines have a higher degree of automation. Thanks to the continuous drive inside the machine and the permanent heating, bags and films can be churned out one after the other. In other words, this sealing process is quicker.

The heat sealers in turn use a third film-sealing technique: They are constantly heated like the continuous rotary heat sealers, but they are operated in a similar way to the thermal impulse sealers.

Just have a browse on our homepage. We offer all three variants to suit all needs.