Impulse sealers

Safe working with medical thermal impulse sealers by polystar®

Medical packaging must be secure – regardless of whether it is primary, secondary or tertiary packaging, as in certain circumstances lives depend on the packaging being secure. Likewise, it doesn’t matter whether or not the packaging contents have been sterilised, but they must be free from unwanted contamination. We want to lend a helping hand here with our medical impulse welding devices.

Regardless of whether or not you need to be able to validate the sealing process, you will find the perfect sealing device by polystar® here.

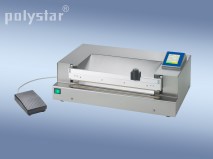

Practical and easy on the eye: polystar® 250 MV in white-blue with USB port, suitable for validation according to DIN EN ISO 11607-2

We wanted to bring a little colour into our medical sealing devices: white to represent clinical cleanliness and blue as the trademark colour of polystar® – the result is a thermal impulse sealer that catches the eye: the 250 MV. From a technical perspective, this sealing device has everything required by validation standard DIN EN ISO 11607: a temperature that can be set to the nearest degree, a sealing and cooling time that can be set to the nearest tenth of a second, pressure control and a saving/documentation option for the parameters via the USB port. On top of that, the parameters are very easy to enter and general operation is delightfully simple.

The sealing device is also practical and, precisely because of that, can be easily integrated into medical or laboratory practice. The film sealer is easy to set up on a work table, allowing you to seal medical packaging at a professional standard.

Work aids such as the plug-in work table and the film dispenser for a roll of sterilisation film in tube form are useful extras, meaning you have everything close to hand and all in one place so you don’t have to slow down.

The series classic: the M-RPA

If you’re into footwork and don’t need to be able to validate your sealing processes, then the M-RPA sealer series is the right choice for you. The stainless steel M-RPA series is robust, reliable and safe and includes two variants for two different seam lengths: 400 and 600 mm.

But just because the M-RPA series is a classic, doesn’t mean it is no longer state-of-the-art... on the contrary! With a temperature that can be set to the nearest degree, a sealing and cooling time that can be set to the nearest tenth of a second and error messages for sealing parameter deviations, it is already very close to validatable quality. The only things missing are the pressure monitoring function and the USB port for recording the sealing parameters.

Of course, the impulse film sealers from the M-RPA series can be turned into proper work stations. Just add a cutting device, a plug-in work table and/or a film dispenser for a roll of tube film and you’re all set for packaging your medical products efficiently and securely.

A true all-rounder among the polystar® medical thermal impulse sealers

Normally, thermal impulse sealers are tailored to specific types of film. You can either use thermoplastic films, e.g. made of polyethylene, or medical sterilisation films. And a special sealer is required for Tyvek® films, as these are particularly sensitive to different sealing devices. So, if you use all these types of film, you will need to buy several sealing devices.

Alternatively, you could go for the polystar® 430 M series. With a working width of 400 or 600 mm depending on the type of sealing device, you can securely seal all types of sealable film – even the tricky Tyvek® film.

The validatable sealing process is started by actuating the foot switch. The strip-heater carriers close and the sequence of preset sealing parameters begins. You can set the temperature to the nearest degree, the sealing and cooling time to the nearest tenth of a second and also the pressure depending on the requirements of the film at hand. The sealing process actually begins when the preset temperature has been reached. Although this creates a slight delay for the first sealing process of the day, it ensures that the required temperature is used. And if you need to carry out a large number of sealing operations one after the other, the residual heat is stored in the heating elements, meaning that there are no more delays.

For the pressure control – which is required for a validatable sealing process – these devices have a secret weapon: The pressure is not only controlled passively, but also adjusted actively and continuously throughout the sealing process. The average values can be saved on a USB stick along with the other sealing parameters. To do this, just plug a USB stick in the port of the thermal impulse sealer.

By the way...

...the fast, reliable and continuously heated polystar® continuous rotary heat sealers can also be used for medical packaging purposes.

Just have a browse on our homepage in the “Medical packaging/Constantly heated sealers” section.