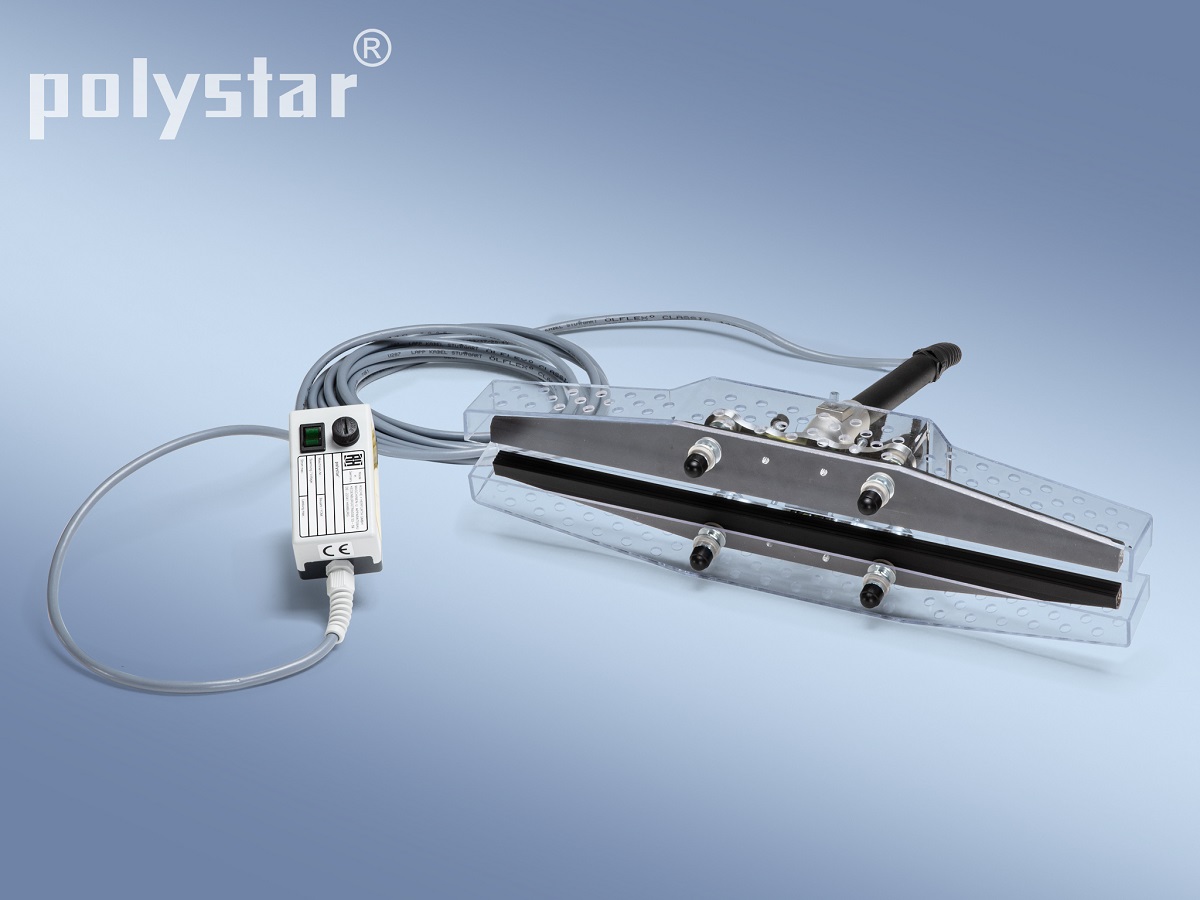

Thermal Sealing Device

Feather-light tongs: Sealing made safe and fast

Permanently heated sealing tongs that are easy to use, lightweight and absolutely safe to handle and work with? What’s that? They don’t exist?

Oh, but they do!

polystar® 400 SZ sealing tongs combine safety and lightweight design in one – and are also GS-tested.

As with all polystar® film sealers and continuous rotary heat sealers, we place a great deal of emphasis on user safety right from the design phase. We have noticed that although there are many permanently heated sealing tongs on the market, very few put safety in the spotlight. Most of the time, the sealing tongs are top-heavy and the handles are unpleasantly hot. The closer you get to the sealing elements, the greater your risk of being burned.

All the more incentive, then, for us to make better tongs – tongs that are safer and easier for you to use.

The design of our 400 SZ sealing tongs was inspired by our thermal impulse sealing tongs. Their ergonomic design has proven effective for decades. In addition, we opted for a cable length of five metres to allow you to work with these permanently heated sealing tongs throughout a wide radius. We have also dispensed with a stationary table clamp with foot pedal, as our experience has shown that our customers value the ability to work flexibly with tongs. With 400 mm-long sealing elements, these tongs can easily seal conventional composite films, aroma-preserving pouches and kraft paper bags with an inner lining of polyethylene.

Heat protection tongs / protection against burns:

- The 400 mm sealing jaws (sealing elements) in the polystar® 400 SZ heat-sealing tongs are behind a protective polycarbonate cover. Only a small amount of heat makes its way through the cooling slots.

- The tong handles are, at most, warm to the touch – thanks to our superior thermal insulation.

- The sealing elements close when not in use and are covered by the protective polycarbonate cover. It is therefore virtually impossible to accidentally burn your hands on these tongs.

polystar® sealing tongs are easy to use:

- Weighing in at just 1.5 kg, they can be used to seal composite films for long periods non-stop.

- They are not top-heavy and therefore make work more comfortable and less tiring.

- Easy to open/close by pressing the handles together/releasing them.

- The sealing process is started when the heat sealing tongs (sealing jaws) are closed.

- The sealing temperature can be set using the turnable pointer knob in the handle.

- The sealing time can be set using the special handle electronics.

- Visual and acoustic status indication.

- Visual and acoustic error signal in the event of deviations/operating errors.

- With 400 mm sealing elements, these tongs are capable of sealing most standard aroma-preserving pouches, composite film zip-lock bags and other sealable films (no PE films!)

Using your hands – using safe sealing tongs is just that easy

Insert the plug in the socket, switch it on, set your sealing temperature and sealing time, wait for the tongs to heat up and away you go! Open the sealing tongs and position the composite film bag between the sealing jaws. Then, simply close the sealing tongs and pay attention to the visual and acoustic status indication. Once the seal is complete, open the tongs again. Remove the sealed composite film with your perfectly protected product. Done! There’s no safer way to package your products.

With the polystar® 400 SZ heat sealing tongs, you can effortlessly seal your high-quality products in aluminium and paper composite films, PA/PE film or PP film, locking out air and locking in aromas.

The tongs can also seal doypack bags and other aroma-preserving pouches in no time at all – all you need to do is adjust the sealing parameters accordingly. This makes the polystar® 400 SZ heat sealing tongs ideal for use in shops of bakeries, pâtisseries and coffee roasters, etc. So you can hand your customer freshly packaged – and aroma-sealed – merchandise ready for the journey home.

Of course, the permanently heated polystar® 400 SZ sealing tongs are also suitable to use for hours at a time – enabling you to handle production runs of large volumes of items without a problem.

By the way, if you would rather use your feet than your hands to seal items, take a look at our permanently heated polystar® 260 HSG heat sealer. This model comes equipped with a foot pedal or foot switch and can create seams of up to 260 mm.

Important: polystar® heat sealing tongs are not suitable for polyethylene films.

If you need to seal polyethylene films or bags, check out our polystar® thermal impulse sealers or the rapid-action continuous rotary heat sealers from the polystar® 350/5 DSM series.

| Technical Data | polystar® 400 SZ | |||

|---|---|---|---|---|

| Max. sealing seam length | 400 mm | |||

| Sealing seam width | 12 mm corrugation | |||

| Sealing temperature | Variable 100 - 220°C | |||

| Input current (peak value) | 1,8 A | |||

| Power consumption (peak value) | 400 watt | |||

| Dimensions | 425 x 300 x 130 mm | |||

| Net weight | 1.5 kg | |||

| Power supply | 230 V/50 Hz | |||

| Sealing tongs delivered with 5 m connection cable. Figures given are approximate. Subject to technical changes. | ||||

Thermal Sealing Device

Thermal Sealing Device Continuous rotary heat sealers for laminates

Continuous rotary heat sealers for laminates