Continuous rotary heat sealers for laminates

Product description

-

Variety is our strength – and we pack a lot!

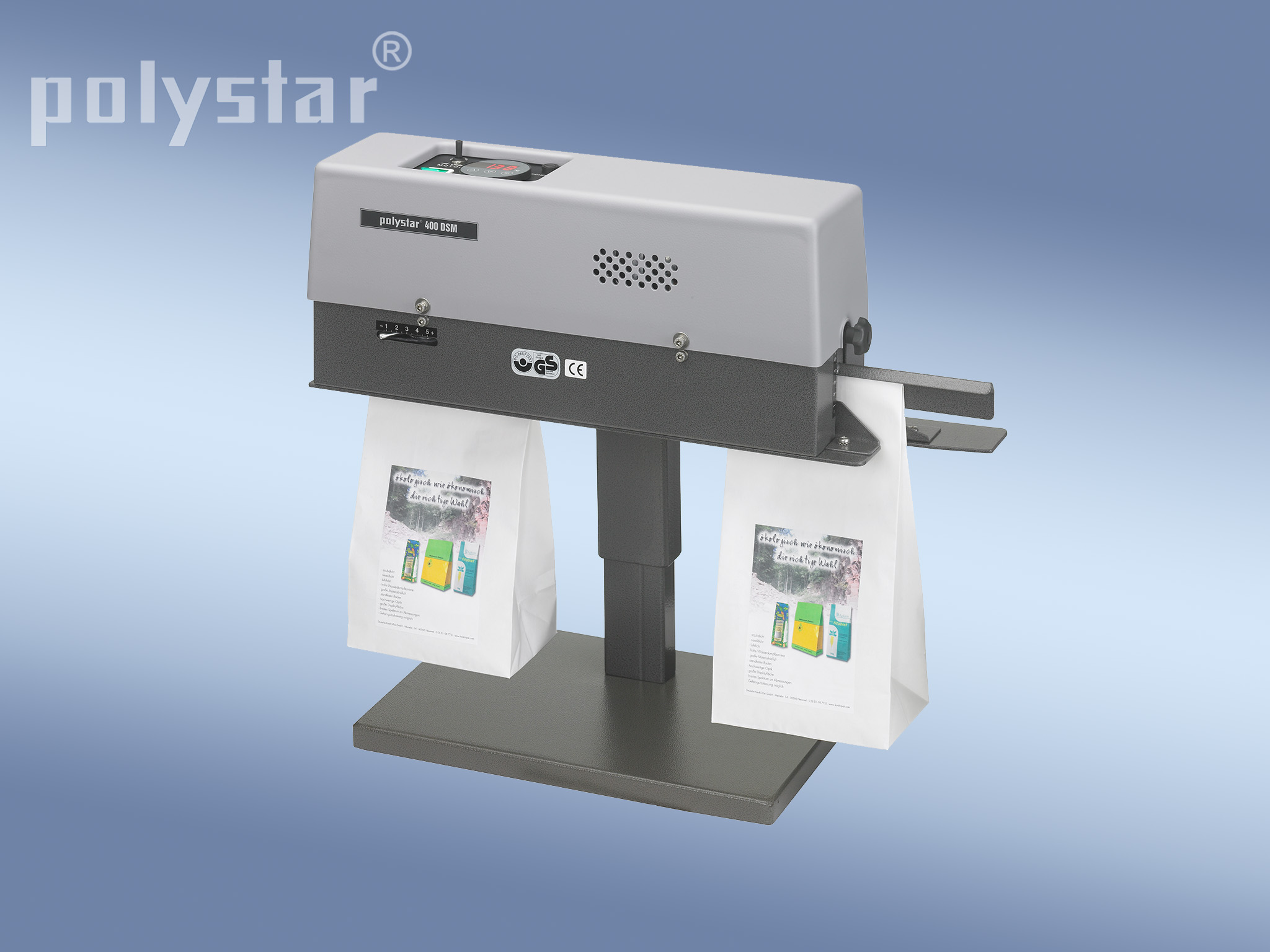

The composite material specialist! Whatever composite material you want to use, these continuously heated sealers from the polystar® 400 and 620 DSM series securely seal everything from aluminium composite films to paper composite films so that your packaging is airtight, aroma-tight and impervious to contamination.

The continuous heating and robust design of the polystar® continuous rotary heat sealers mean that they can be used for long periods of time without a hitch – e.g. in the V2A variant for the food industry, for sealing in aromas, for applying card header labels, etc. Coated paper and aluminium bags up to 0.80 mm thick are securely sealed thanks to the spring-mounted embossing rollers. What’s more, the exceptionally quiet stepper motor makes for a pleasant working environment. And so, when running, the polystar® 400 and 620 DSM sealers can hardly be heard, but the sealing results are clear to see.

It is easy to spot the difference between the polystar® sealers of the 400 DSM series and 620 DSM series: the bag is fed in vertically in the 400 DSM series, whereas in the 620 DSM series it is lying down. Also, the 620 DSM series is available in V2A as standard.

The standard sealer of the polystar® 400 and 620 DSM series is extremely versatile: it can output 6.7 meters per minute, no matter whether the composite film has to be sealed two or even four times for side-gusseted bags!

We know that packaging comes in all shapes and sizes. We have therefore devised special solutions for the polystar® continuous rotary heat sealers of the 400 and 620 DSM series:

- polystar® 400/3 DSM with 3 meters per minute for particularly thick barrier films, even with side gusset

- polystar® 400/6.7 DSM-H: Bags can be sealed up to 80 mm below the edge at the standard speed. Ideal for bags with carrying handles

- polystar® 400 DSM with speed control. Just adapt the speed to the different bag materials and thicknesses.

- polystar® 400/6.7 DSM with precise temperature control. Some materials are very temperature-sensitive, e.g. polypropylene films and polyamide/polyethylene composite films. The sensitive temperature sensor eliminates temperature fluctuations and thus provides a perfect sealing result.

- polystar® 400/6.7 DSM-V with extended and motorised V-infeed. This special machine is particularly effective in combination with a motorised table conveyor belt or a large mobile conveyor belt. Just put the filled stand-up pouch on the running belt. The belt then transports the pouch automatically through the V-infeed into the sealing area of the continuous rotary heat sealer. The pouch is then completely sealed when it exits the machine.

- polystar® 400/6.7 DSM zipper. Pouches with a zip, e.g. doypacks, can be sealed and the zip closed in one step – it couldn’t be simpler. We even have different variants of the zipper bag sealers to cater for the different zipper heights (distance from bag edge).

- polystar® 620 DSM with 6.7 meters per minute and precise temperature control seals all composite bags in the horizontal position with a 12 mm corrugated seam.

- polystar® 620 DSM-HC with smooth embossing rollers applies header cards with a PE inner coating effortlessly onto the bag. This sealer also comes with a precise temperature control function.

- "Typically, all polystar® continuous rotary heat sealers run from right to left. But upon request it can also be set to run from left to right."

- The continuous rotary heat sealers of the 400 DSM series come with powder-coated side plates. But if you prefer, these side plates can be replaced with V2A plates. These machines are therefore completely safe to use in the food industry.

Important: The polystar® 400 DSM, 620 DSM and 620 DSM-HC are not suitable for polyethylene bags!

To seal polyethylene bags or polyethylene film, use our thermal impulse sealers or the rapid-action continuous rotary band sealers from the 350/5 DSM series.

Technical data

-

Technical data polystar® 400 DSM polystar® 620 DSM polystar® 620 DSM HC Speed 6,5 m/Min. 6,5 m/Min. 6,5 m/Min. Passage height 30 mm 30 mm 30 mm Seal width 12 mm 12 mm 12 mm Sealing material thickness 0,8 mm 0,8 mm 1 mm Power consumption 0,5 kWh 0,4 kWh 0,4 kWh Dimensions 610 x 160 x 210 mm 620 x 310 x 190 mm 610 x 210 x 190 mm Net weight 12,0 kg 17,0 kg 15,0 kg Power supply 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz All machines are supplied with a 3m connecting cable. The measurements given are approximate.

We retain the right to make technical changes without giving prior notice! Videos

-

Documents

Thermal Sealing Device

Thermal Sealing Device Thermal Sealing Device

Thermal Sealing Device Stainless steel filling scales

Stainless steel filling scales