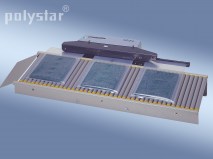

polystar 350 DSM

polystar 350 DSM

Continuous band sealers for polyethylene film

Product description

-

Bags big and small: No sealing order is too tall!

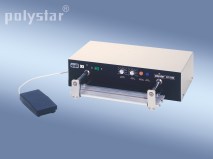

The fastest of our polystar® continuous rotary band sealers can manage 10 m/min, but the standard speed of 5 m/min is not exactly slow. Its universal usability makes it an indispensable tool for when polyethylene bags up to 0.60 mm thick need to be sealed against air, dust and water in quick succession.

All polystar® continuous rotary band sealers of the 350 DSM series are continuously heated and have spring-mounted cooling rails that are automatically set to the relevant film thickness. This guarantees a constant pressing pressure, which in turn guarantees constant sealing results with a 4 mm wide seam. While the standard polystar® 350 DSM variant is suitable for lightweight pouches of up to 150 g, the TE variant can cope with bags weighing up to 500 g entirely on its own. Heavier bags of up to 25 kg can also be reliably sealed with the help of a roller track or conveyor belt, for example.

We know that packaging comes in all shapes and sizes – which throws up new challenges for you and us every day. Our answer to this is our practical modular system. Combine any of the following machine variants to create a sealing machine that meets your precise specs:

- polystar® 350 DSM and 350 DSM-TE. Produces seam widths of 6 mm or 8 mm or 2x5 mm double seams.

- polystar® 350 DSM-H und 350 DSM-TE-H. For sealing PE bags up to 150 mm below the bag edge. In this way, carrier bags can conveniently be sealed below the carrying handle.

- polystar® 350 DSM and 350 DSM-TE with precise temperature control. The ideal choice for temperature-sensitive packaging materials such as polypropylene films, cellophane and non-wovens. The digital thermostat prevents the temperature from fluctuating and thus creates perfect sealing results.

- polystar® 350 DSM-TE-SV. An integrated cutting tool trims off the excess bag material above the sealing seam. Fully automatic, fully unproblematic.

- polystar® 350 DSM-TE with smooth-running wheels with matching and individual frame. Large and cumbersome bags or pouches and sheets of film are sealed effortlessly.

- "Typically, all polystar® continuous rotary heat sealers run from right to left. But upon request it can also be set to run from left to right."

- The polystar® continuous rotary band sealers of the 350 DSM and 350 DSM-TE series come with powder-coated side plates. But if you prefer, these side plates can be replaced with V2A plates. These machines are therefore completely safe to use in the food industry.

All variants of the continuous rotary band sealers can additionally be fitted with work aids. We offer the following work aids:

- Table stand: The polystar® continuous rotary sealer is secured on the table stand to ensure a smooth sealing process. The height can be adjusted either using a wing screw or a hand crank.

- Guide rail: Seal your bags, pouches or sheets of film at the same height.

- Roller track: For supporting heavier pouches of up to 2 kg. For vertical or horizontal bag sealing (only in combination with the polystar® 350 DSM-TE variant).

- Table conveyor belt: For supporting heavier pouches of up to 7 kg. For vertical or horizontal bag sealing (only in combination with the polystar® 350 DSM-TE variant).

- Conveyor belt: For supporting heavier pouches or bags of up to 25 kg. The height can be adjusted either using a wing screw, a hand crank or – as a new feature – electrically.

Our continuous rotary heat sealers from the 400 and 620 DSM series are perfect for sealing composite film bags.

Technical data

-

Technical data polystar® 350/5 DSM polystar® 350/10 DSM polystar® 350/5 DSM-TE polystar® 350/10 DSM-TE polystar® 350/5 DSM-H Speed 5 m/Min. 10 m/Min. 5 m/Min. 10 m/Min. 5 m/Min. Passage height 30 mm 30 mm 30 mm 30 mm 150 mm Seal width 4 mm 4 mm 4 mm 4 mm 4 mm Sealing film thickness PE 2 x 0,3 mm 2 x 0,15 mm 2 x 0,3 mm 2 x 0,15 mm 2 x 0,3 mm Power consumption 0,3 kWh 0,3 kWh 0,3 kWh 0,3 kWh 0,3 kWh Dimensions 400 x 90 x 220 mm 400 x 90 x 220 mm 510 x 80 x 240 mm 510 x 80 x 240 mm 400 x 90 x 340 mm Net weight 6,5 kg 6,5 kg 7,0 kg 7,0 kg 11,0 kg Power supply 230V / 50Hz 230V / 50Hz 230V / 50Hz 230V / 50Hz 230V / 50Hz All machines are supplied with a 3m connecting cable. The measurements given are approximate.

We retain the right to make technical changes without giving prior notice! Videos

-

Documents

Portable Impulse Tong Sealers

Portable Impulse Tong Sealers Hand-guided continuous band sealers for polyethylene film

Hand-guided continuous band sealers for polyethylene film Electromagnetic table-top sealers, vertical sealing jaws

Electromagnetic table-top sealers, vertical sealing jaws Electromagnetic table-top sealers, horizontal sealing jaws

Electromagnetic table-top sealers, horizontal sealing jaws Electromagnetic table-top sealers, vertical sealing jaws, electronic regulation

Electromagnetic table-top sealers, vertical sealing jaws, electronic regulation Electromagnetic table-top sealers, horizontal sealing jaws, electronic regulation

Electromagnetic table-top sealers, horizontal sealing jaws, electronic regulation Stainless steel filling scales

Stainless steel filling scales